- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

中国 アイソスタティックグラファイト メーカー、サプライヤー、工場

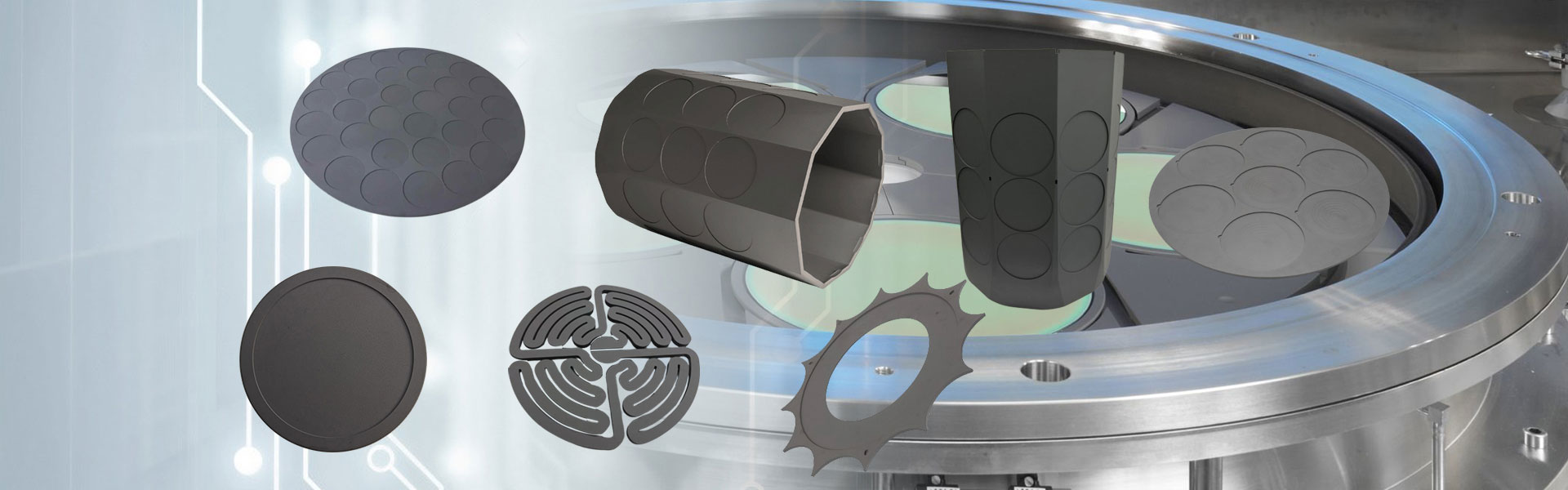

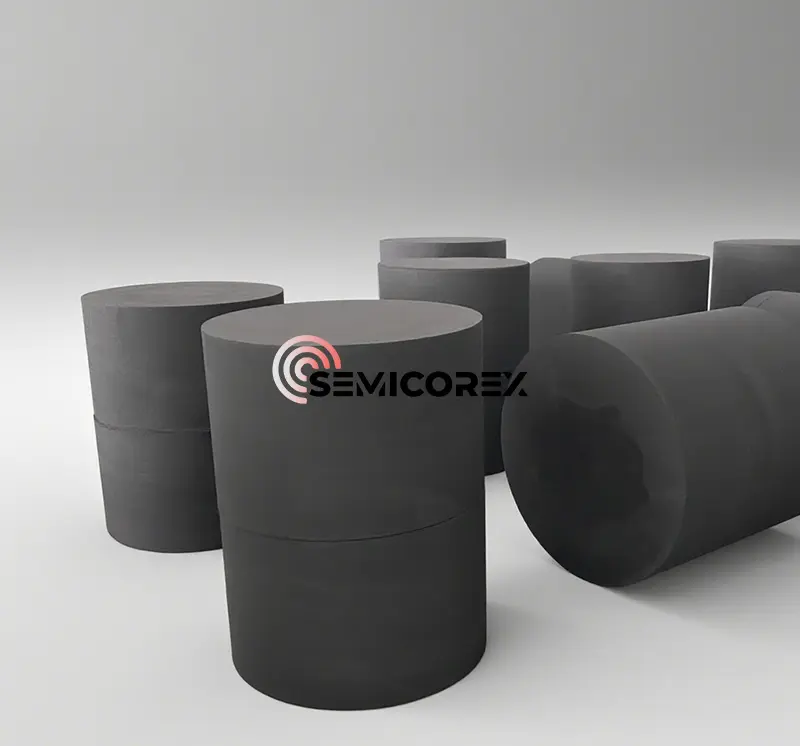

Carbon/graphite material molding essentially involves increasing the density of the powder mixture and ensuring close contact between the aggregate and binder to produce a green body with a desired size, morphology, and minimal machining allowance. The four main molding methods are extrusion, compression molding, vibration molding, and isostatic pressing. Common carbon/graphite materials on the market (for example, charcoal used for household fires) are mostly formed using hot extrusion and compression molding (cold or hot). Isostatic pressing offers superior molding performance.

The principle of isostatic pressing is based on Pascal's law: pressure applied to a medium (liquid or gas) in a sealed container is uniformly distributed in all directions, with the pressure on the surface being proportional to the surface area. Isostatic pressing involves placing a sample, enclosed in a sealed container, within a high-pressure cylinder. Leveraging the incompressible nature of the liquid medium and its ability to uniformly transmit pressure, the sample is uniformly pressed from all directions. When the fluid is injected into the cylinder, the pressure is evenly transmitted in all directions according to the principles of fluid mechanics. The sample in the cylinder is then subjected to uniform pressure in all directions.

Due to the isostatic pressing method, isostatically pressed graphite exhibits excellent isotropy, with properties independent of shape, size, or sampling direction. The material possesses a dense microstructure, high mechanical strength, high surface hardness, and oxidation resistance. Strong performance and high-temperature resistance; the material has excellent thermal shock resistance and is less susceptible to cracking under rapid cooling and heating conditions.

1. Isotropy

Different molding methods result in different properties in different directions. This is primarily reflected in resistivity, thermal conductivity, mechanical properties, and thermal expansion coefficient. The general measurement method is to sample the product perpendicular to and horizontally from the pressure surface, measure the properties separately, and then divide the smallest value by the largest value to obtain the isotropy ratio.

Traditional carbon/graphite products exhibit significant anisotropy, i.e., the properties of the product are different in the directions perpendicular to and horizontal to the pressure surface. The corresponding difference in performance is generally greater than 1:1.1, hence the term anisotropy. In many cases, this difference is fully exploited, and the greater the difference, the better. Examples include graphite electrodes for steelmaking and brushes for motors. Many applications, such as EDM and single-crystal silicon thermal field applications, increasingly require carbon/graphite products to exhibit isotropy (with an orientation ratio within the 1:1.05 range).

2. Large Dimensions

The market is increasingly demanding larger product sizes. For example, single-crystal silicon products have grown from 6- and 8-inch sizes to 12-inch sizes. The size of graphite materials used in thermal fields is also increasing. This is also increasing. Similar trends are seen in other related industries. Graphite for EDM, continuous casting, and nuclear reactors also requires large-scale products. This is difficult to achieve using molding and extrusion methods. The primary problem with large-scale product production is calcination cracking, and the larger the product, the higher the chance of calcination cracking.

3. Fine Structure

As a structural material, it requires high physical and chemical properties. On the one hand, the finer the particle size of the carbon particles that make up the carbon/graphite material, the denser its texture and the higher its mechanical strength.

Isostatically pressed graphite is widely used in semiconductor manufacturing processes. It is used in graphite components for the hot zone of single crystal growth furnaces, such as crucibles, heaters, flow guides, and insulation covers; and in graphite components used in epitaxial processes.

- View as

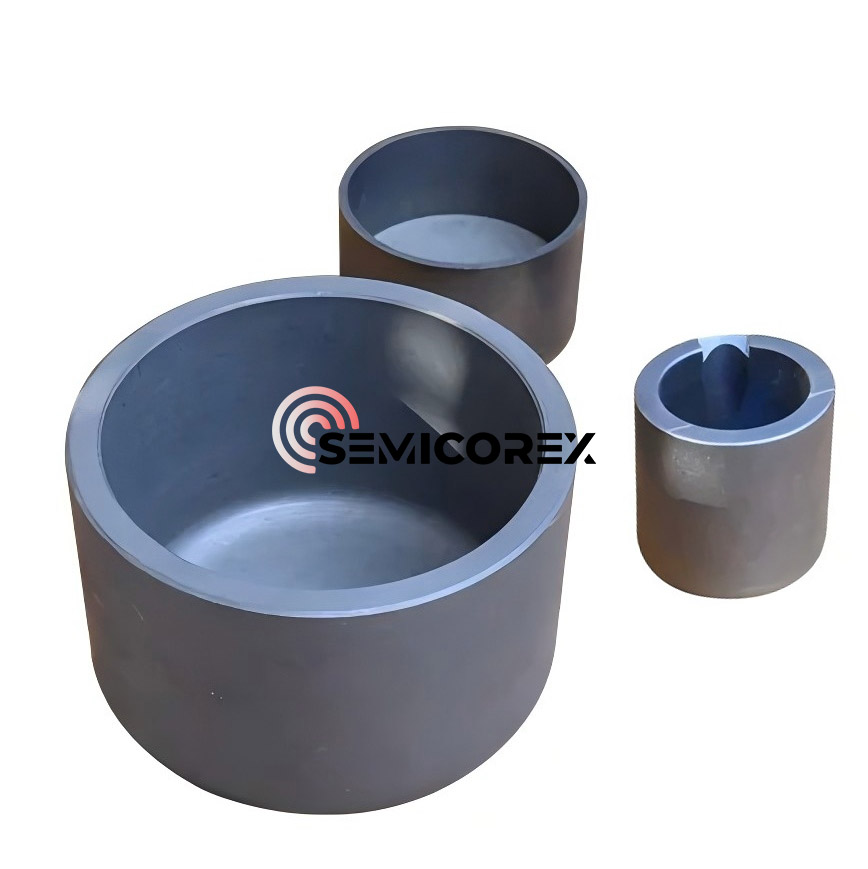

SiC コーティングされたグラファイトるつぼ

SiC コーティングされたグラファイトるつぼは、炭化ケイ素でコーティングされたグラファイト材料から精密機械加工された必須の容器であり、優れた高温耐性と耐化学腐食性を備えています。 Semicorex の SiC コーティングされたグラファイトるつぼは、優れた性能と信頼性の高い品質を備えており、制御された高品質の結晶生産を実現するための最適なソリューションです。

続きを読むお問い合わせを送信含浸グラファイトロッド

Semicorex 含浸グラファイト ロッドは貴重な機械加工品で、機械業界で広く使用されている高品質の含浸グラファイトで作られています。 Semicorex は、高品質のグラファイト製品を提供する中国のトップ企業です。*

続きを読むお問い合わせを送信グラファイト銅スリーブ

Semicorex グラファイトカッパースリーブは、潤滑を独自の潤滑剤に依存するタイプのスリーブです。製品は銅合金を基材とし、基材に規則正しく適切な大きさの穴を開け、グラファイトプラグを埋め込みます。 Semicorex は、完成したグラファイト銅スリーブ、またはカスタマイズされたグラファイト プラグを供給できます。*

続きを読むお問い合わせを送信カーボングラファイトベアリングとブッシュ

Semicorex のカーボン グラファイト ベアリングとブッシングは、機械産業で広く使用されている高品質のカーボン グラファイトで作られています。 Semicorex は、お客様の要件に基づいて認定された製品を提供します。*

続きを読むお問い合わせを送信グラファイトベアリング

Semicorex グラファイトベアリングは、自己潤滑性、耐高温性、耐食性、軽量などの点で大きな利点を持っており、機械の駆動用としてさまざまな業界で広く使用されています。 Semicorex は、お客様をサポートするために適格な製品を提供することに尽力しています。*

続きを読むお問い合わせを送信