- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

中国 アルミナ(AL2O3) メーカー、サプライヤー、工場

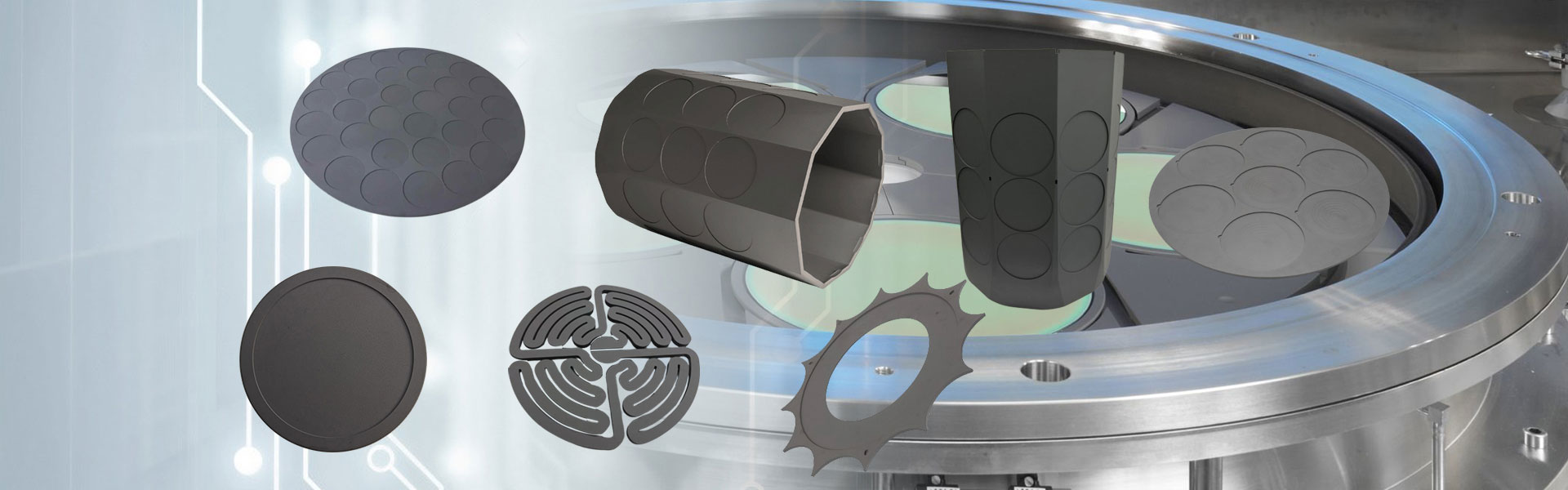

Alumina ceramics are a type of advanced ceramic material that is primarily made of aluminum oxide and the general purpose of ceramists. They are in great demand because of their remarkable comprehensive properties, some of which include high hardness, high wear resistance, and high temperature resistance. These will maintain their structure at very high temperatures. Additionally, alumina ceramics have high electrical insulation and chemical resistance, and very high mechanical strength. While brittleness will limit them. They possess all those properties which has resulted in alumina ceramics playing a central role in the semiconductor industry.

The vacuum chuck will be attached to the vacuum equipment via a connecting pipe. When the chuck comes in contact with the workpiece, i.e., a sheet or film, the vacuum equipment will activate and draw negative pressure in the chuck. The workpiece is carried by atmospheric pressure thus it will cling firmly to the chuck allowing the processing to go on without issue. When the workpiece is done being processed the vacuum machine will stop and the chuck will gradually fill with air. The workpiece will separate of its own accord thus finishing the clamping, processing and handling processes.

Black Alumina ceramic is one of the primary materials used in vacuum chucks. It is primarily composed of Al2O3, with transition metal oxides as colorants and sintering aids added. The process is then sintered at a specific temperature. Vacuum chucks made from porous ceramic feature ultra-fine micrometer-level pores and spacing, enabling reliable handling of thinner and more delicate workpieces. Furthermore, these chucks can accommodate workpieces of varying sizes, eliminating the need to maintain a fixed set of shapes and sizes for each workpiece, thus saving costs and improving efficiency.

Alumina ceramics have a high elastic modulus and specific stiffness, are resistant to deformation, and have a low coefficient of thermal expansion and high thermal stability. They are an excellent structural material and are currently widely used in aviation, aerospace, petrochemicals, machinery manufacturing, the nuclear industry, and microelectronics.

Alumina ceramic components offer excellent properties such as high hardness, high mechanical strength, exceptional wear resistance, high temperature resistance, high resistivity, and excellent electrical insulation. They can meet the complex performance requirements of semiconductor manufacturing in special environments such as vacuum and high temperature. They play an irreplaceable and important role in semiconductor manufacturing production lines, covering nearly all semiconductor manufacturing equipment and serving as key components. Alumina ceramic components are primarily categorized by application, including annular and cylindrical types, airflow guides, load-bearing and fixed types, hand-grip gaskets, and modules.

- View as

多結晶アルミナ繊維板

多結晶アルミナ繊維板は、耐熱衝撃性、耐食性、耐酸化性に優れた高性能耐火板材です。この耐火性能により、高温炉、高温窯、高温反応器、高温パイプライン、高温炉ドア、高温炉壁などの厳しい高温環境で広く使用されています。 Semicorex を選択すると、非常に費用対効果の高い価格、パーソナライズされた 1 対 1 のカスタマイズ サービス、優れた製品品質の恩恵を受けることができます。

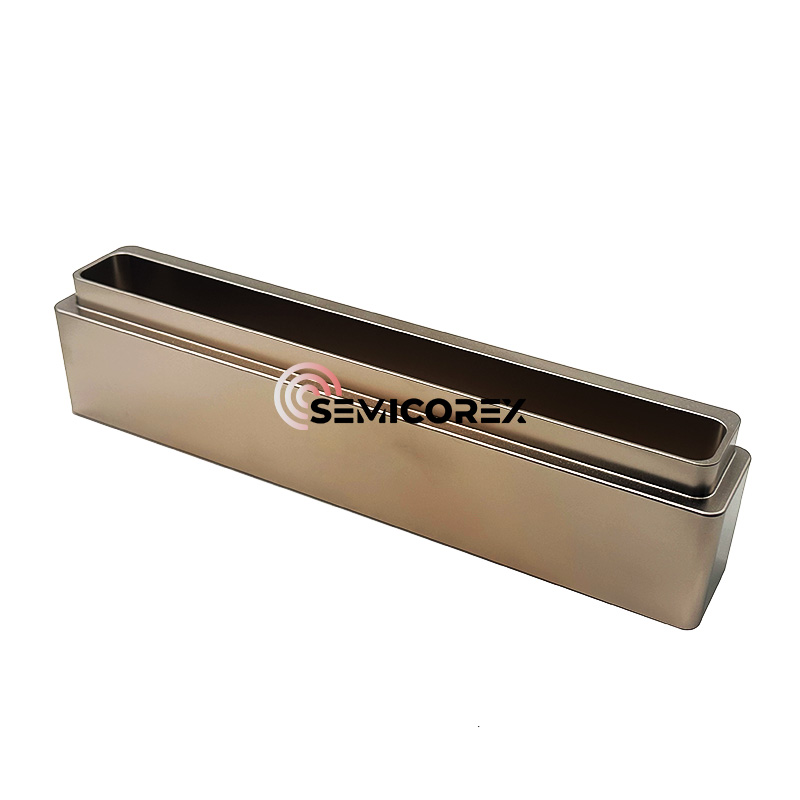

続きを読むお問い合わせを送信カスタマイズ可能なセラミックノズル

Semicorex のカスタマイズ可能なセラミック ノズルは、細部まで細心の注意を払って製造されており、比類のない均一性と精度で気体と液体の両方の流量を制御するための天才的なソリューションです。セミコレックスでは皆様のご相談を心よりお待ちしております。

続きを読むお問い合わせを送信セラミック静電チャック

セミコレックスセラミック静電チャックは、高性能アルミナおよび窒化アルミニウムセラミックスを使用し、静電吸着の原理を利用してウエハをクランプ・固定する精密静電吸着部品です。半導体製造分野で広く使用されています。 Semicorex は高度な技術、高品質の素材、コスト効率の高い製品を備えています。私たちは中国における信頼できる供給パートナーとなることを楽しみにしています。

続きを読むお問い合わせを送信アルミナセラミックマニピュレーター

Semicorex アルミナ セラミック マニピュレータは、高純度アルミナ製の高性能半導体装置コンポーネントで、汚染のないウェーハを正確に取り扱うために特別に設計されています。このマニピュレータは、優れた清浄度、優れた安定性、高精度、強化された効率、信頼性の高いパフォーマンスの特性を備えており、理想的な選択肢となります。

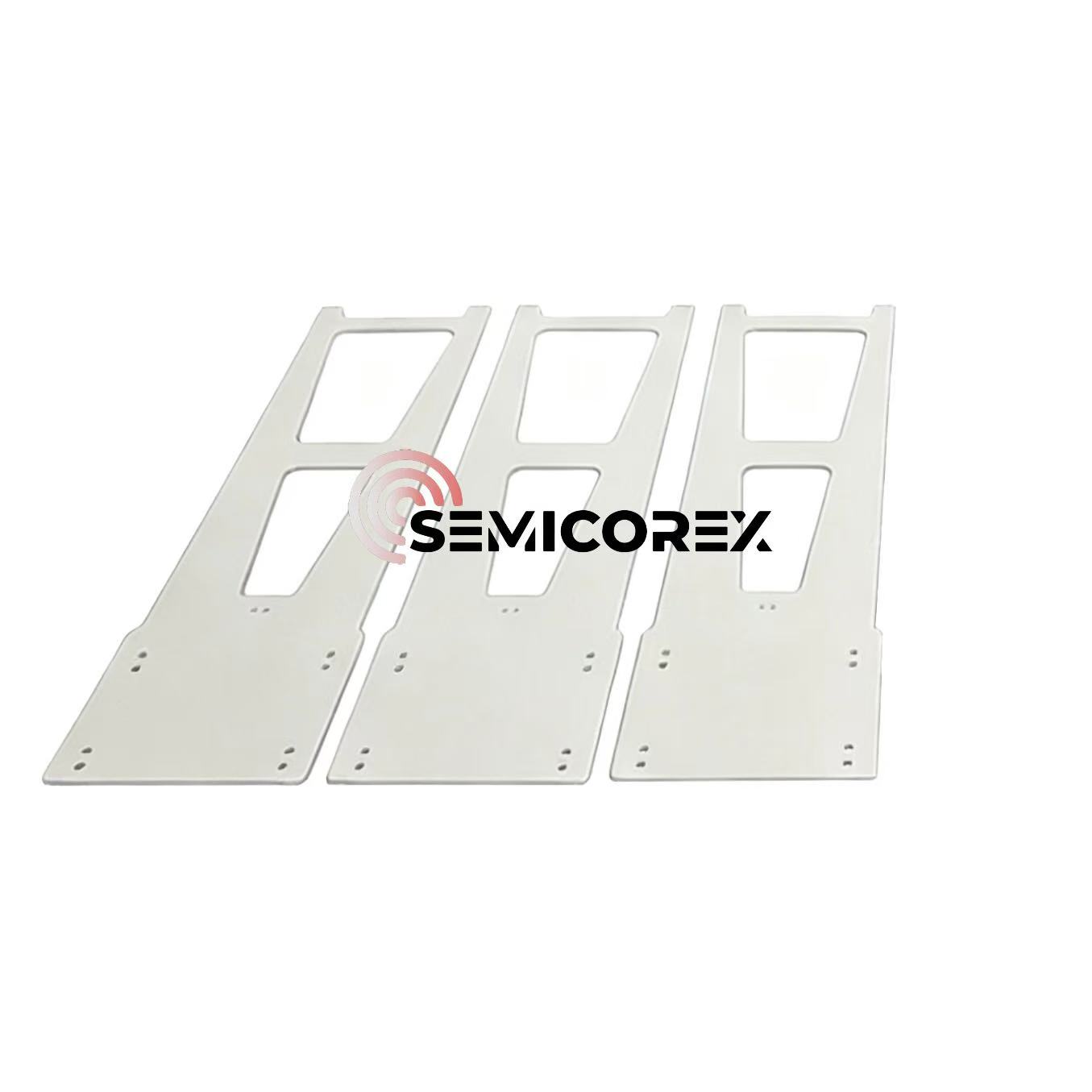

続きを読むお問い合わせを送信アルミナの取り付けベースプレート

セミコレックスアルミナ取り付けベースプレートは、半導体製造における正確なウェーハの取り扱いのために設計された高性能セラミックコンポーネントです。その優れた強度、断熱、および熱安定性により、クリーンルームの自動化環境を要求するのに最適です。

続きを読むお問い合わせを送信アルミナロボットアーム

Semicorex Alumina Robot Armは、半導体製造における正確なウェーハ処理のために設計された高性能セラミックコンポーネントです。その優れた強度、断熱、および熱安定性により、クリーンルームの自動化環境を要求するのに最適です。

続きを読むお問い合わせを送信