- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

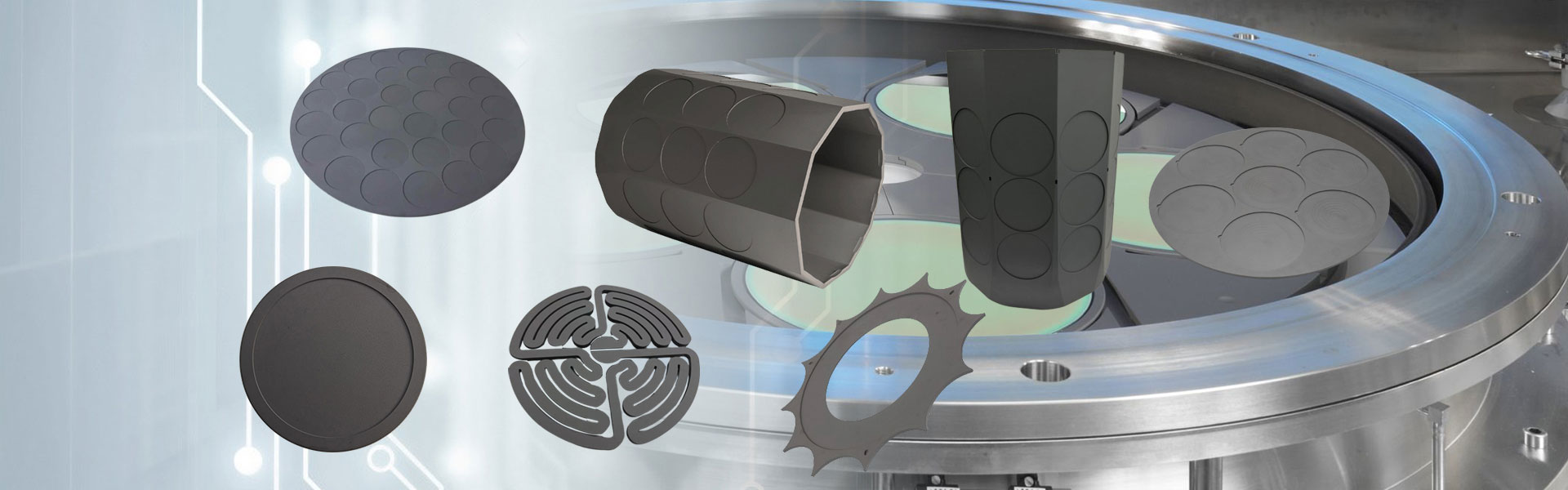

中国 特殊グラファイト メーカー、サプライヤー、工場

- View as

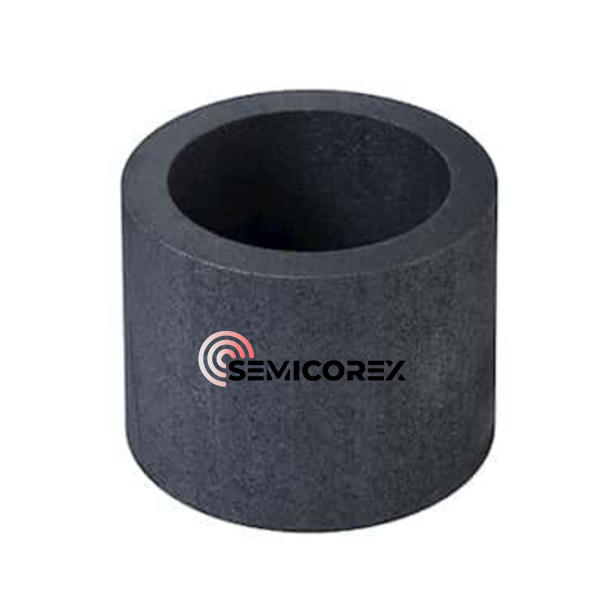

グラファイトブッシュ

Semicorex グラファイト ブッシングは、その独自の材料特性と適応性により、機械システムの性能と寿命を向上させる上で重要な役割を果たし、現代のエンジニアリングおよび製造プロセスにおけるその重要性を強調しています。

続きを読むお問い合わせを送信

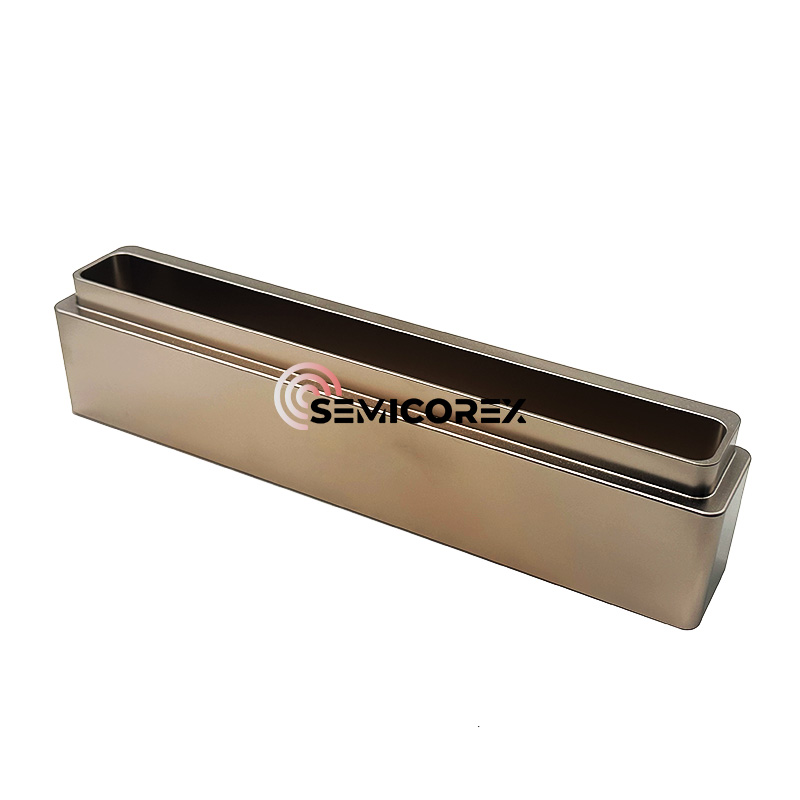

Semicorex は 特殊グラファイト を長年生産しており、中国のプロの 特殊グラファイト メーカーおよびサプライヤーの 1 つです。バルク梱包を提供する高度で耐久性のある製品を購入すると、迅速な配達で大量の製品を保証します。長年にわたり、お客様にカスタマイズされたサービスを提供してきました。お客様は当社の製品と優れたサービスに満足しています。私たちはあなたの信頼できる長期的なビジネスパートナーになることを心から楽しみにしています!私たちの工場から製品を購入することを歓迎します。