- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

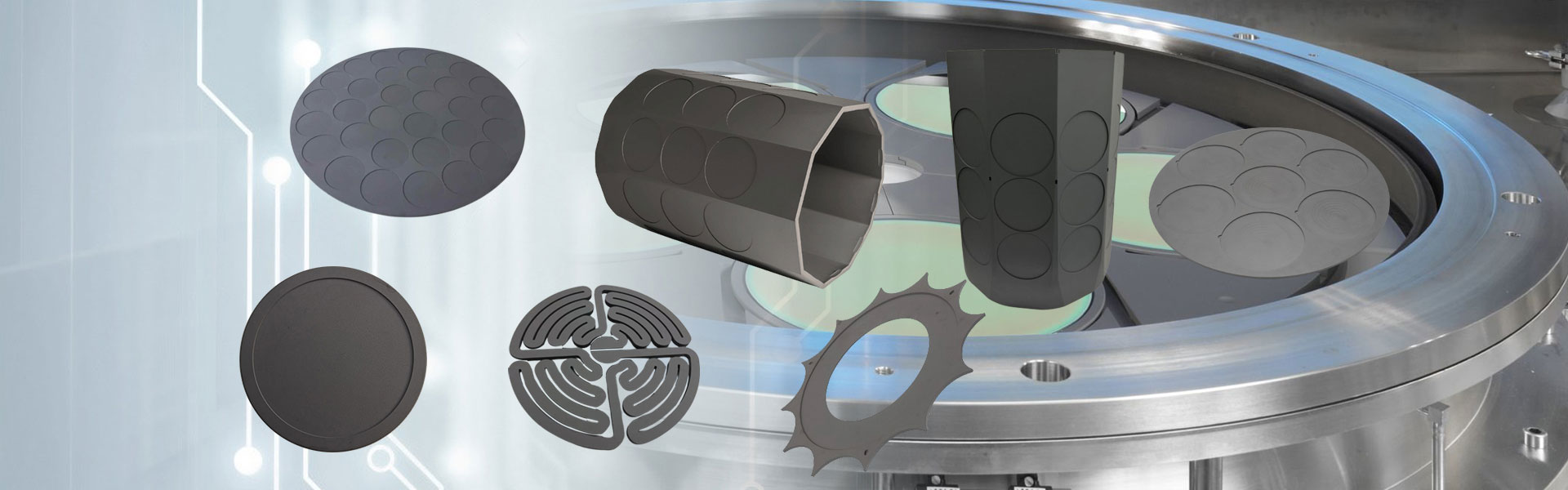

中国 特殊グラファイト メーカー、サプライヤー、工場

- View as

炭素繊維硬質フェルト

Semicorex 炭素繊維硬質フェルトは、高温環境、特に半導体結晶成長プロセスで使用するために設計された高性能材料であり、るつぼや絶縁ライニングなどの重要なコンポーネントとして機能します。 Semicorex は、優れた熱安定性、寸法精度、耐久性を備えた高度で高品質な材料を提供し、半導体製造における最適なパフォーマンスと効率を保証します。*

続きを読むお問い合わせを送信グラファイトフェルト

Semicorex グラファイト フェルトは、柔軟性、軽量、高効率の断熱材で、高温用途に最適です。 Semicorex は、優れた耐久性と信頼性を実現する高品質のグラファイト フェルトを提供しており、高度な断熱ソリューションを要求する業界にとって最適な選択肢となっています。

続きを読むお問い合わせを送信ガラス状カーボンコーティングを施した硬質フェルト

ガラス状カーボンコーティングを施したセミコレックス硬質フェルトは、カーボンファイバーフェルトの耐久性と、傷がつきにくく防塵性のあるガラス状カーボンコーティングを組み合わせた高性能断熱材です。 Semicorex の高度なコーティング技術に関する専門知識により、卓越した耐久性と清浄性が保証され、高温および精度が重要な用途の要求に応えます。*

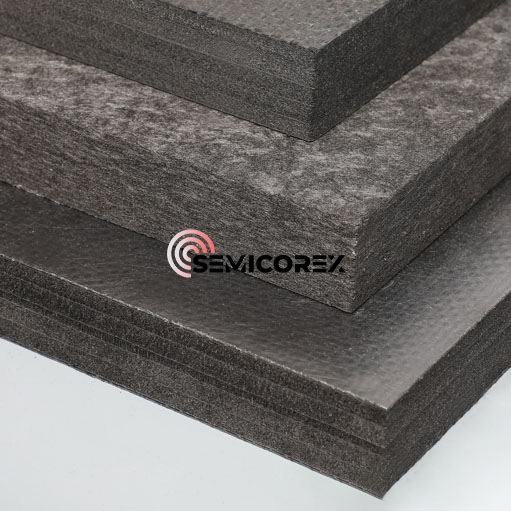

続きを読むお問い合わせを送信グラファイト硬質フェルト

Semicorex グラファイト硬質フェルトは、高温用途向けに設計された高性能素材であり、優れた圧縮強度と優れた断熱性を備えています。 Semicorex を信頼できるパートナーとして、より高い産業目標を達成しましょう。*

続きを読むお問い合わせを送信ガラス状カーボンコーティング硬質フェルト

セミコレックスの代表的な製品であるガラス状カーボンコーティング硬質フェルトは、ガラス状カーボンコーティングで覆われた炭素繊維硬質フェルト基材で構成され、フェルト本来の強度とガラス状カーボンの優れた表面特性を組み合わせています。 。これらを組み合わせることで、極限の条件下でも優れたパフォーマンスを発揮する素材が生まれます。**

続きを読むお問い合わせを送信